VIP member

Hasco (Tangshan Iron and Steel) Company in the United States

Hasco (Tangshan Iron and Steel) Company in the United States

Product details

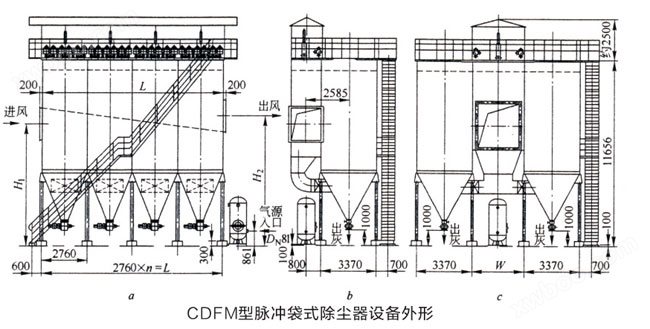

CDFM large and medium-sized pulse bag filter

◆ Characteristics

The spray device itself has low resistance, wide pulse opening and closing quickly, so the spray pressure is below 0.1-0.25MPa

The length of the filter bag is bm, and the footprint is relatively small.

3. The filter bag is easy to remove and replace, with short contact between people and dust bags, and good operating conditions.

The computer controller or PLC equipped with 4 accessories works reliably and is easy to adjust.

The 5 large and medium-sized pulse bag filter is a dust removal equipment developed to meet the needs of larger wind installations. Its characteristics are long filter bags and a large quantity

The equipment is compact and capable of handling large amounts of dusty gases.

◆ Working principle

The dusty gas is introduced from the lower part of the middle box, guided by the baffle to the upper part of the middle box and enters the filter bag, while the clean gas is discharged from the upper box. For large and medium-sized enterprises

For dust removal equipment, the design of airflow guiding baffles is crucial. A good baffle can make the flow field inside the dust collector more reasonable, thereby enabling

To reduce equipment resistance and improve dust removal efficiency.

The connection between the pulse valve and the spray pipe adopts a plug-in method. There are spray nozzles with varying aperture sizes on the blowing pipe, aimed at the center of each filter bag. press

The standard design shares a pulse valve for every 15 bags, and there is no injection Venturi tube at the bag opening.

To eliminate the phenomenon of dust reattachment after pulse blowing, there is also a pulse bag filter for offline dust cleaning with air stop. It will

The upper box is divided into several small chambers, each equipped with a shut-off valve. When the pulse valve of a certain room sprays, close the air stop valve of that room and cut off the dusty gas

Flow, thereby increasing the cleaning effect. The spraying time is 65-85ms per time, which is 50% shorter than the traditional small pulse cleaning time and can produce more dust

Strong dust cleaning effect. The dust cleaning control adopts a constant pressure difference control method, or can be timed control.

Online inquiry